- Industries

-

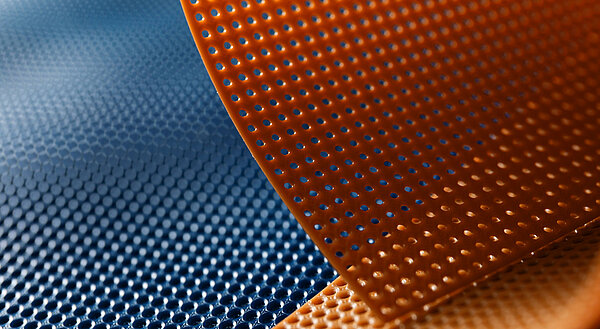

Materials

Materials

MaterialsAs a neutral and independent testing service provider, we offer analyses of the highest quality for a wide range of products.

-

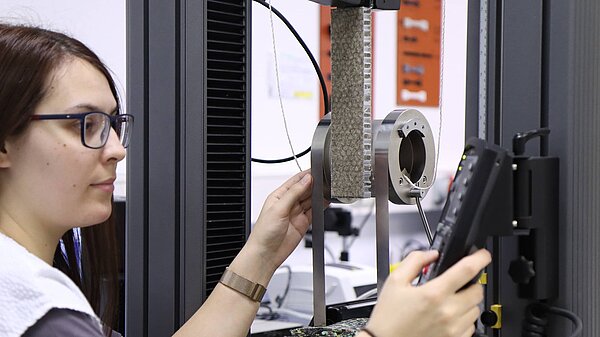

Test procedures

Test procedures

Test proceduresAs a neutral and independent testing service provider, we offer analyses of the highest quality for a wide range of products.

- Accreditation

- Company

- Contact

OMPG - Ostthüringische Materialprüfgesellschaft für Textil und Kunststoffe mbH

Breitscheidstraße 97

07407 Rudolstadt

| Phone | + 49 3672 379 - 0 |

| info@ompg.de |

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/f/csm_mikroskopie_471dba580a.jpg)