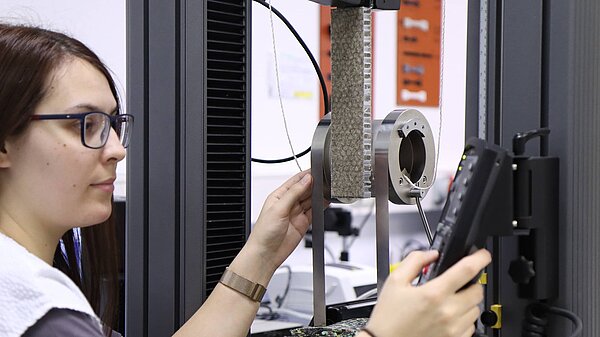

A Crockmeter is used to test color fastness/friction fastness during the international round robin tests. (Image montage: OMPG / Steffen Beikirch)

In round robin tests, several test laboratories examine identical samples using mostly identical test methods. The tests are organized by independent testing institutions such as the German Reference Office for Interlaboratory Tests and Reference Materials Kempten (DRRR), OFI Technologie & Innovation GmbH Vienna (Austria), Testex AG from Zurich (Switzerland) or the iis Institute for Interlaboratory Studies from Spijkenisse (Netherlands). They organize the tests, send the test materials and evaluate the results.

“Our participation provides us with important information for our quality assurance,” says Susann Olschak, Quality Management Officer at OMPG. “Every round robin test ties up capacity and costs participation fees. Nevertheless, it is a sensible investment and not just working through a specification,” says Olschak. “This is because it identifies potential sources of error at an early stage. If necessary, processes within the inspection services can be corrected or the personnel and technical equipment can be usefully supplemented. And last but not least, our employees receive feedback on the quality of their work.”

Every year, the Rudolstadt test laboratory takes part in up to 30 round robin tests. Last year, for example, it took part in four international interlaboratory tests conducted by Testex AG in the areas of yarn testing, color fastness and fabric properties in accordance with various ISO standards. In order to cover the entire range of services, OMPG also took part in interlaboratory tests in the areas of materials testing (including melt flow index, bending tests on Dynstat specimens and tensile tests on films and leather) and consumer goods (nickel resistance, plasticizers, heavy metals, etc.).

In addition, Volkswagen AG invited tenders for an approval ring test on the emission behavior of materials in vehicle interiors in accordance with the VW 50180 standard. OMPG has been participating in these “comparative tests” of the car manufacturer for 20 years and was again confirmed by VW as an approved laboratory for initial sample tests in 2020.

This year, participation in more than 20 round robin tests is planned. A test on color fastness is already underway. And in March, interlaboratory tests on differential scanning calorimetry (DSC) in the field of thermal analysis are scheduled.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)