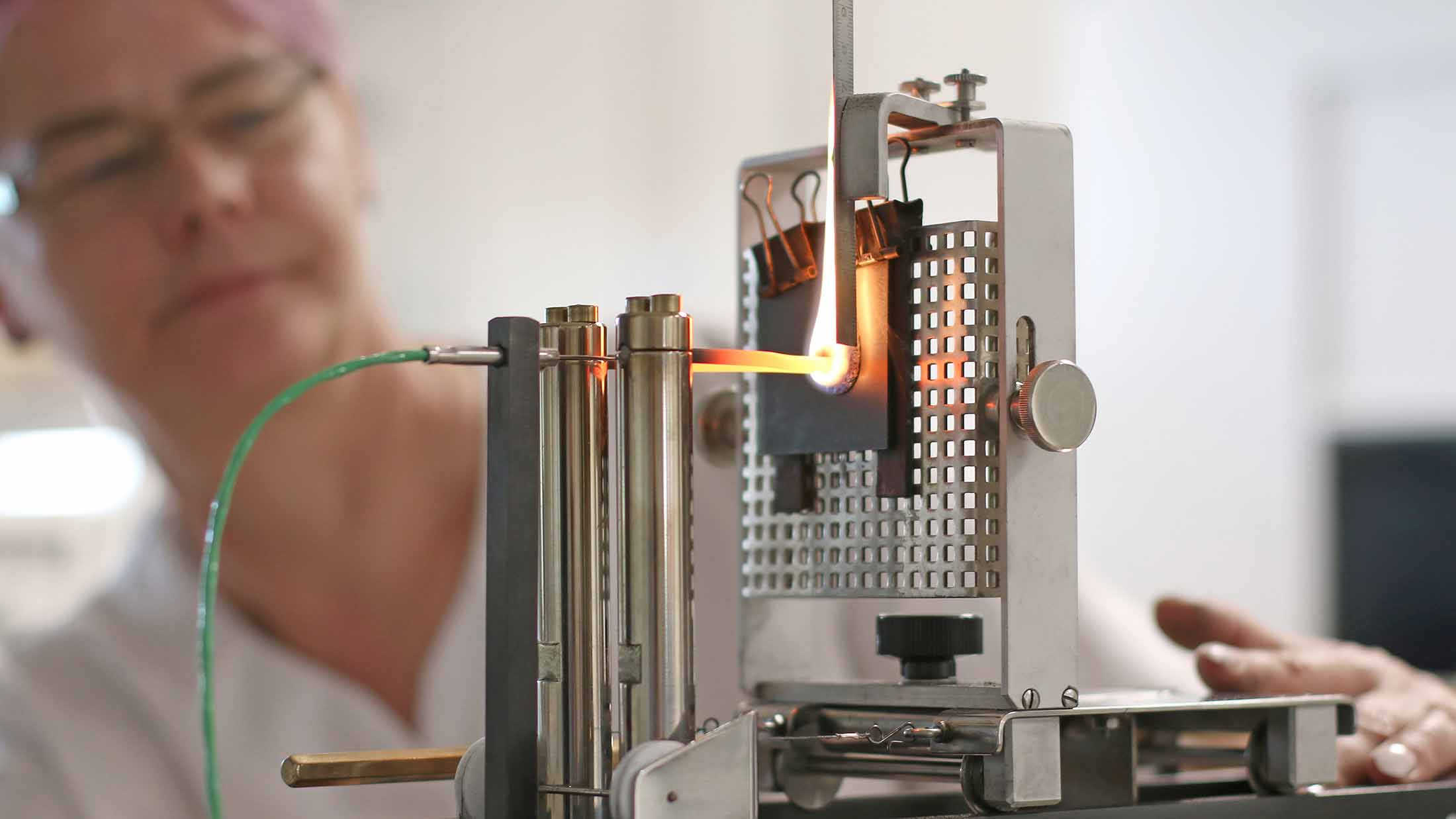

Laboratory technician Sigrun Bayer carries out a glow wire test in accordance with the DIN standard. (Photo: OMPG / Steffen Beikirch)

How well and for how long a material, a semi-finished product or a finished product must withstand the flames is determined primarily by its intended use, its installation position and also the future environmental conditions. The test methods used are as diverse as the potential causes of fire. “The 'fire sources' alone range from classic Bunsen burner flames, glowing wires and radiant heaters to live electrodes and electrolyte solutions,” says Ute Schwarz, head of the plastics testing laboratory at OMPG.

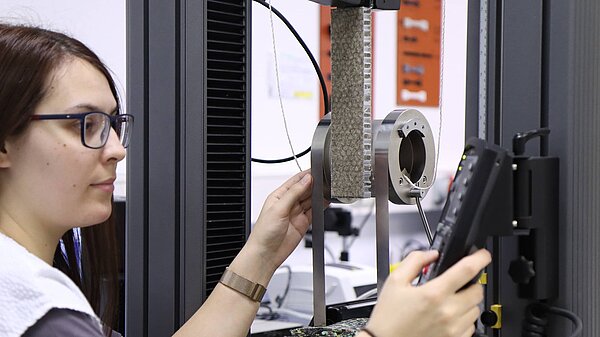

As a testing service provider within the TITK Group, OMPG offers a wide range of flammability tests. And the accredited laboratory also provides a wealth of experience from more than 30 years. In this area, OMPG has specialized in the testing of automotive supplier and electrical components. The UL94 fire testing standard rounds off the range of services.

At OMPG, the focus here is on “small fire tests” that can be carried out in fume cupboard systems. “It is important to note that a standardized fire test only simulates a fire scenario under precisely defined conditions and it is almost impossible to draw conclusions about a real fire,” emphasizes Ute Schwarz. Most fire tests compare different materials with each other or operate with precisely defined specifications derived from practice, Schwarz continues.

However, new technological developments are also changing the priorities of testing services. Originally, almost only simple horizontal fire tests in a special fire box were used in the automotive sector (FMVSS 302 or DIN 75200), but with the increasing construction of electric vehicles, tests from the electrical sector are also moving into the focus of the industry.

OMPG is active in both areas of plastics testing and can offer fire tests in accordance with the specifications of the various automotive manufacturers as well as glow wire (GWIT / GWFI) and leakage current tests (PTI / CTI).

Such flammability tests can also be experienced first-hand on site in Rudolstadt. The following tests, among others, will be presented at the OpenHouse event at OMPG on March 19, 2025 (participation free of charge):

- UL 94 (flammability of plastics) - HB (horizontal) and V (vertical)

- Fire testing for automotive applications - e.g. DBL 5307, TL 1010, GMW 3232

- Cone calorimeter and smoke box / flue gas chamber - ISO 5560 / ISO 5659

- Glow wire test (thermal stress caused by glowing parts or overloaded electrical resistors) - DIN EN IEC 60695-2-10, -11, -12, -13

- Leakage current resistance DIN EN IEC 60112

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)