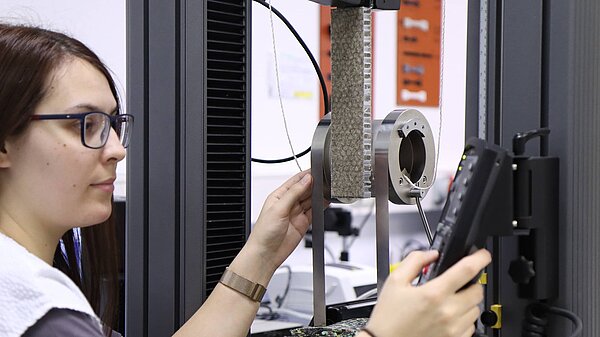

Fatima Körfer (left) and Marie Thiel from OMPG's Chemical Analysis department determine the evaporated substances during a test in accordance with VDA 278. (Photo: OMPG / Steffen Beikirch)

The testing service provider from the TITK Group had already been certified in 2017 by the former Daimler AG for various emission tests, such as odor, fogging, 1,3-butadiene and formaldehyde. In accordance with the new DBL 1000 works standard, OMPG continues to be approved by the Mercedes-Benz Group for VDA 270 (odor) and is now also approved for VDA 278 (organic emissions). The laboratory has been accredited for both by the German Accreditation Body (DAkkS) for over five years.

Emission testing in accordance with VDA 278 is based on the principle of thermodesorption. This involves heating small sections of components in sealed sample tubes to a precisely defined temperature of 120 degrees Celsius and determining the vaporized substances using gas chromatography in combination with a mass spectrometer. Both the quantity and the composition of the emissions are analyzed.

Various car manufacturers use this method to specifically search for hazardous substances in automotive components during the approval process. The aim is to exclude their emissions in the car interior as far as possible.

“The analysis method used can also be used for tests with the micro test chamber method in accordance with DIN ISO 12219-3 for road vehicles in order to determine emissions from composite components close to the point of use,” says Ute Schwarz, Laboratory Manager for Plastics Testing at OMPG.

OMPG has received further approvals from automobile manufacturers from Volkswagen AG for the test standards PV 3341 (emissions of organic compounds, “headspace” method for short), PV 3015 (condensable components, “fogging” for short) and PV3925 (formaldehyde content) as well as PV 3900 (leather / odor). All of these standards are contained in VW 50180 (Emission behavior in vehicle interiors).

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)