To this end, the laboratory was audited for the DIN EN ISO 20743, ISO 22196 and DIN EN ISO 10993-5 standard procedures by both the German Accreditation Body (DAkkS GmbH) and the Central Authority of the Federal States for Health Protection with regard to Medicinal Products and Medical Devices (ZLG). This means that these test procedures can now be carried out on textiles, plastics and medical devices.

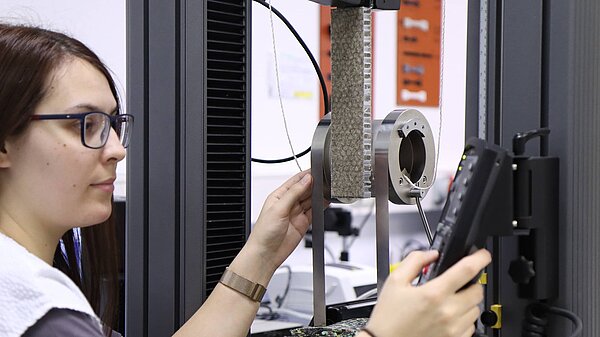

OMPG has been a competent and reliable testing service provider for many companies in the automotive, textiles and toys industries since 1992. New laboratories have now been set up for testing biological properties and test methods for determining antibacterial efficacy and body compatibility have been established.

The international standard DIN EN ISO 20743 “Textiles - Determination of antibacterial efficacy of textile products” is used to determine the antibacterial efficacy of textiles. In the procedure, bacterial pathogens are applied to the test material, removed again after an appropriate exposure time and then the number of live bacteria is determined. A quantitative assessment of the antibacterial efficacy is made by calculating the difference in growth compared to the control material.

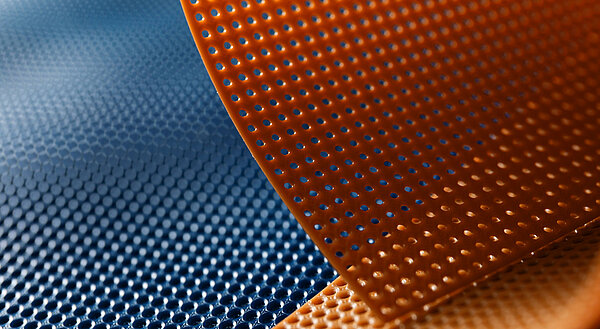

The OMPG also offers testing of plastics and other smooth surfaces in accordance with the international standard ISO 22196 “Plastics - Measurement of antibacterial activity on plastic and other non-porous surfaces”, which is based on the Japanese standard JIS Z 2801. Here, pathogens such as Staphylococcus aureus or Escherichia coli are also applied to the material surface and removed again after an appropriate contact time. This is a very sensitive method, so that even very small, harmful influences on the bacteria lead to a positive antibacterial result. It is therefore advisable to adapt the test conditions to the application and thus examine the antibacterial effectiveness under “more stringent” conditions, says Dr. Bauer, head of the laboratory.

The trend towards equipping materials with antibacterial properties not only requires qualified proof of their antibacterial effect, but also includes the need to test their compatibility with the human body.

For this reason, the test method for in-vitro cytotoxicity in accordance with DIN EN ISO 10993-5 “Biological evaluation of medical devices - Part 5: Tests for in-vitro cytotoxicity” has also been included in the test portfolio.In the test procedure, extracts of the materials are added to connective tissue cells.After an appropriate contact time, the vitality of the cells is first determined visually using a microscope and then using a biochemical method.

The quantitative evaluation allows a quick and sensitive assessment of the toxic properties of the material, whereby a loss of vitality of more than 30 % is considered critical. Investigations of material modifications or chemical analyses can be used to identify the toxic components.

For the current year, the OMPG is planning to expand the accredited test procedures with regard to biocompatibility testing to include skin irritation (OECD 439) and corrosion (OECD 431) tests as animal-free in vitro methods.

These tests are carried out on cultured skin models and thus offer the possibility of limiting animal testing in accordance with DIN EN ISO 10993-10 “Biological evaluation of medical devices - Part 10: Tests for irritation and skin sensitization”.The test portfolio of antibacterial tests is also being expanded with the accreditation of the standard procedure in accordance with DIN EN ISO 20645 “Textile fabrics - Testing of antibacterial activity - Agar plate diffusion test”.

With the new biology laboratory and the accredited test methods, OMPG now offers a quality-assured, biological test spectrum for a wide range of test materials.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)