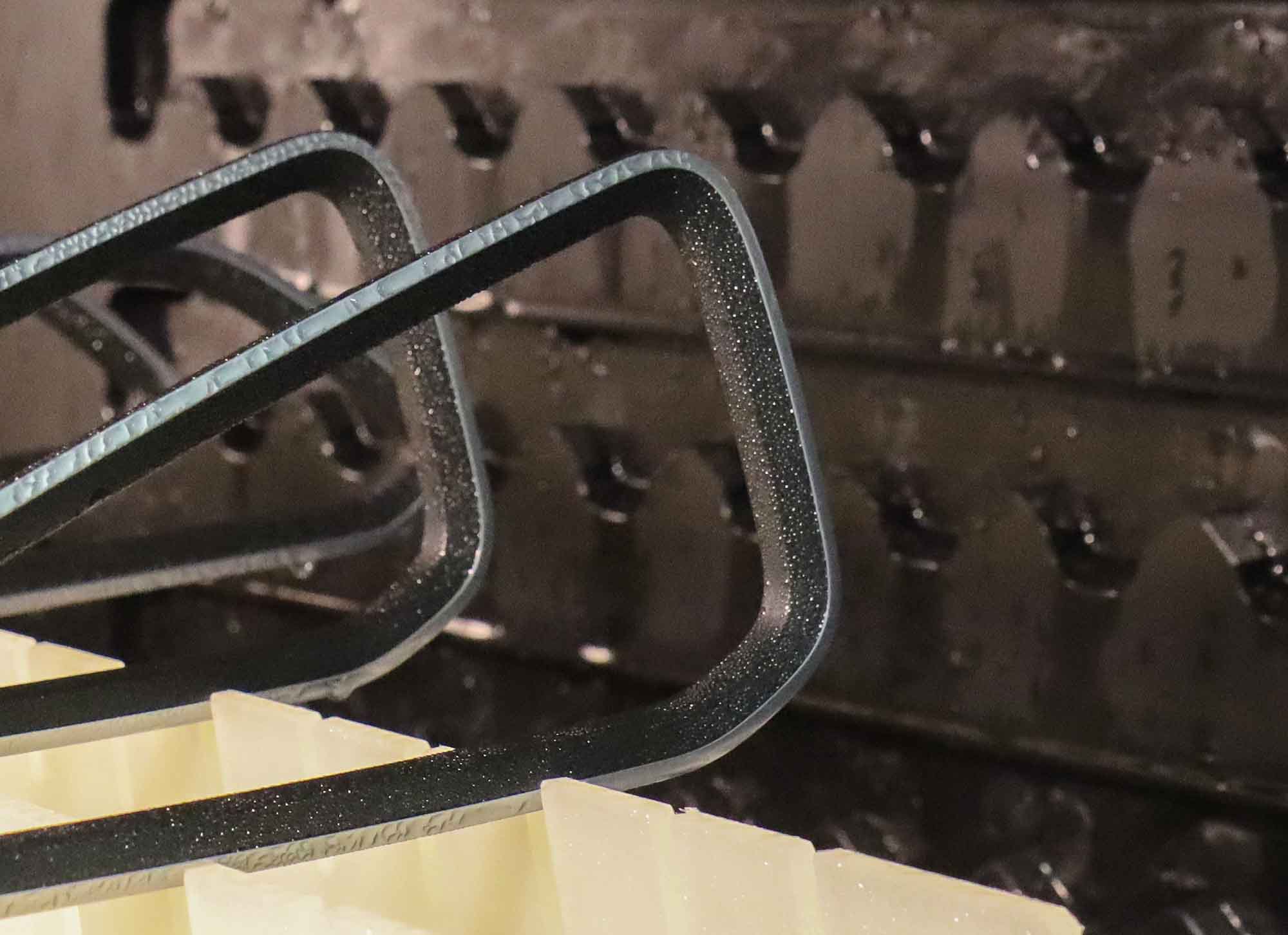

Laboratory technician Stefan Crone equips the 606-Basic test chamber for a test in accordance with DIN EN ISO 6270-2 CH. (Photo: OMPG / Steffen Beikirch)

In this test method in accordance with DIN EN ISO 6270-2 CH/AT, the sample parts or specimens have to withstand the permanent effects of condensation water. For this purpose, the test specimens are stored under precisely defined conditions in a climate chamber with a heated water tank. At temperatures of 40 degrees Celsius (+/-3 degrees) and almost 100 percent humidity, condensation forms on the material.

The resistance of the surface is assessed on the basis of various criteria. For example, visually perceptible changes such as the formation of bubbles. The surface adhesion of coated materials can also be examined more closely using various methods, such as the cross-cut, cross-cut or scratch test.

“The condensation water constant climate test is particularly important for manufacturers of coated assemblies and plastic parts, as these parts are often used in conditions where humidity and temperature differences play a major role”, explains laboratory manager Christian Hauspurg from OMPG. This applies in particular to parts that are used outdoors or in climatically extreme regions.

For Hauspurg, the most important advantages of condensation constant climate testing are that the coating quality of the test specimens can be checked very reliably. Weak points can therefore be identified quickly and subsequent complaints avoided. “At best, our test report also serves as proof of the durability of the parts”, says Hauspurg.

OMPG has two different test chambers available for this test procedure:

- Test chamber CON 300FL CWC with a test chamber volume of 300 liters

- Test chamber 606-Basic with a test chamber volume of 400 liters (can also be used for the salt spray test according to DIN EN ISO 9227-NSS)

As a competent partner to many coating users, OMPG can also offer numerous other resistance tests (climate, light, weather, temperature, media, etc.) including the corresponding evaluation options as well as visual and mechanical measurement of color and gloss.

Do you require further information or would you like to contact our experts directly? If so, Christian Hauspurg and his deputies Kristin Probst and Lidija Gomboc Szabó will be happy to help you. Write an email to prueflabor@ompg.de or visit us at our OpenHouse event on March 19, 2025 in Rudolstadt, Thuringia!

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)